The one I am tackling with this product development is the coil charging clip. I am on my third factory clip.

The little contact pins break, or the plastic spring breaks.

| The clip is positioned on the coil by just a few points, not solid surfaces. This allows too much misalignment as you install the clip onto the coil. Misaligning it means you need to open the clip jaws beyond the limit of the plastic spring so it breaks. Now you find yourself wrapping rubber bands around the clip jaws, or other makeshift fixes. Pushing down to make contact between the pins and the contact pads on the coil while misaligned will cause the spring pins to bend and or break. |

They break, and usually at the most inopportune time.

Besides the breakage issues, I do not like where the USB plug is located. I find it is not the most convenient position. And since the clip jaws lock onto the bottom of the coil, the clip protrudes on the bottom. Many times I get it on the coil and charging, only to have it pop off when I set the coil down.

1. Eliminate the plastic spring.

2. Eliminate the spring pins.

3. Locate the clip to the coil using as many surfaces (not points) as possible so it fits snug with no rocking.

4. Clip should not protrude below the bottom of the coil.

5. Move the USB port to be more accessible.

6. Beef the body up to make it generally less prone to breakage.

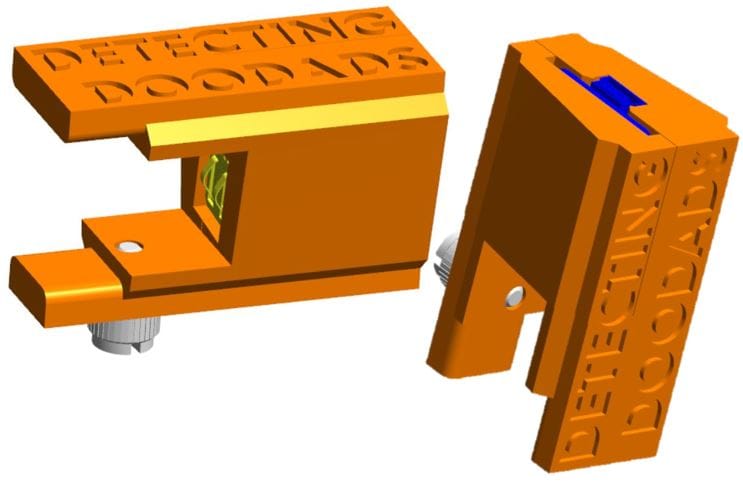

So I started by modeling up the section of coil this clip must fit.

Now I simply design a clip that fits the exact dimensions of every surface of the coil where needed.

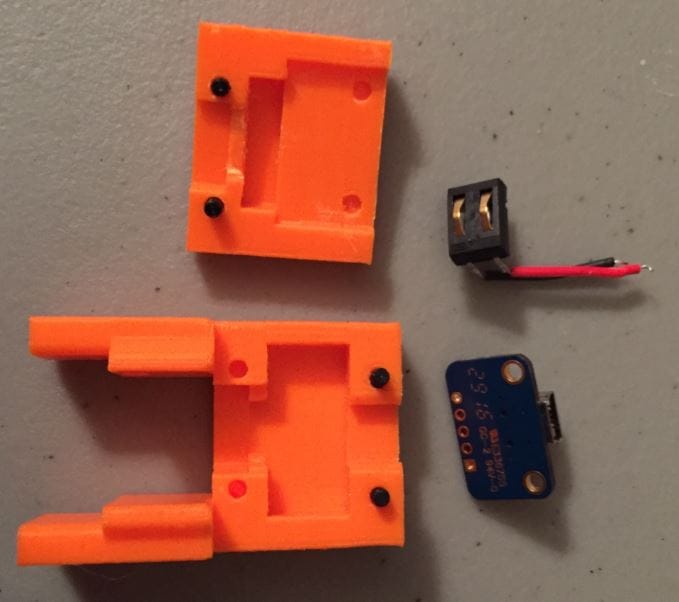

Now to find a replacement for the spring pins. I tested larger spring pins but the first one simply fell out of its socket and the spring bounced out to freedom. The contact pads on the coil are only 3/16" apart. This limits the size of the mating contacts in the clip. After searching long and hard I found these cool gold plated nickel leaf spring contact modules. Leaf springs are single components that are very tough and forgiving. This works really well.

The other component is the Mini USB socket. I found these nice break-out-board mounted units that give me good mounting and solder points.

Model those components, design them into the bottom half of the clip, split the assembly so I can put the two electronic components in and solder them together. 3D print the clip body, assembly and test it out.

It is rock solid on the coil without any rocking around. This is due to the many surfaces the clip references on.

My goal is for this to be the best and only Deus charging clip you will every need to buy again.

RSS Feed

RSS Feed